Science News: Recent scientific discoveries and expert analysis

Read the latest science news and recent scientific discoveries on Live Science, where we've been reporting on groundbreaking advances for over 20 years. Our expert editors, writers and contributors are ready to guide you through today's most important breakthroughs in science with expert analysis, in-depth explainers and interesting articles, covering everything from space, technology, health, animals, planet Earth, and much more.

Explainers | Everything you need to know about the science news that matters.

Science Spotlight | Shining a light on new science transforming our world.

Latest news

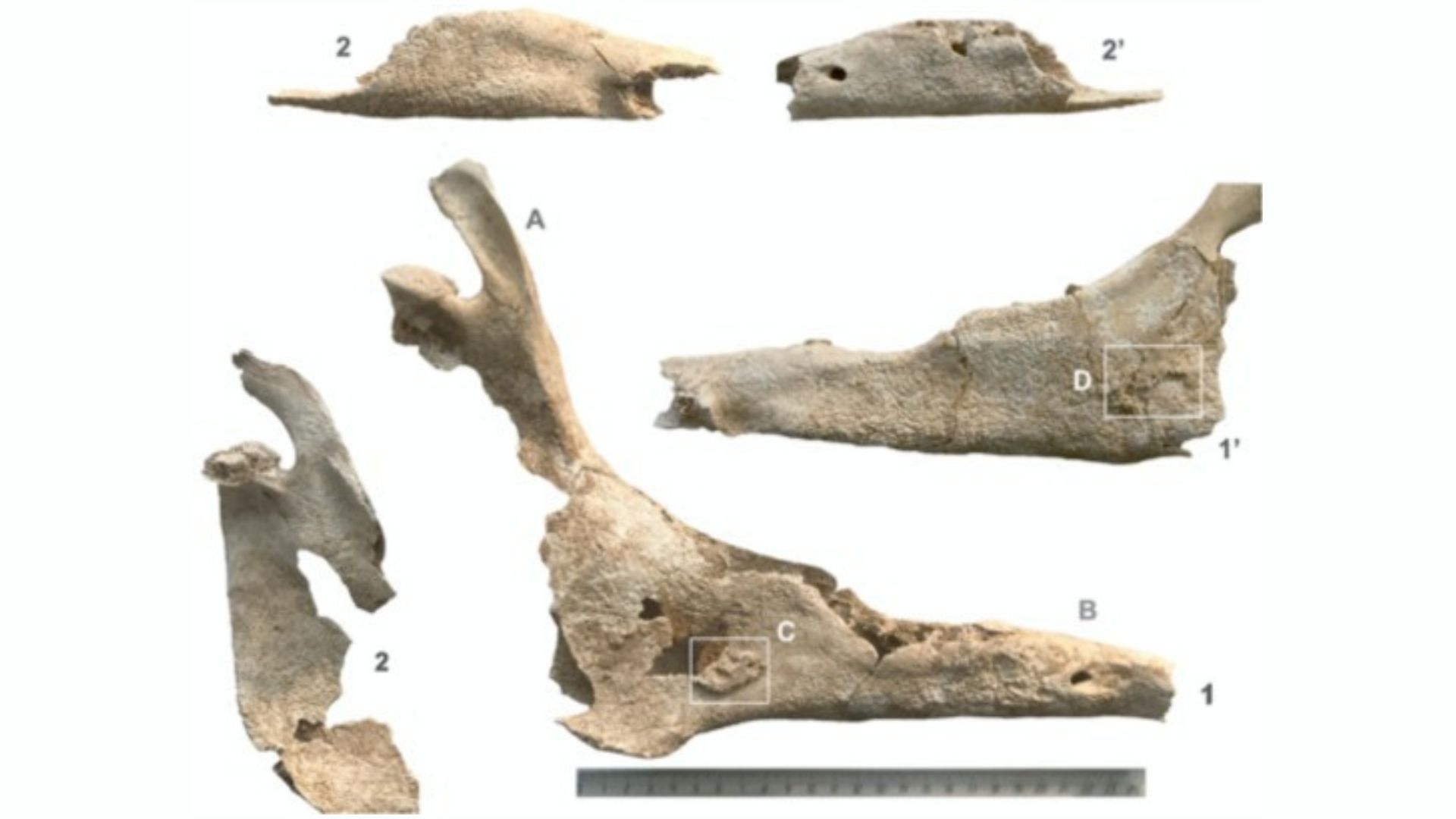

Western Europe's earliest known mule died 2,700 years ago — and it was buried with a partially cremated woman

By Owen Jarus published

Scientists have identified the oldest mule remains ever found in the western Mediterranean.

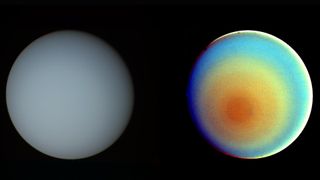

Something supercharged Uranus with radiation during Voyager flyby 40 years ago. Scientists now know what.

By Skyler Ware published

Forty years ago, Voyager 2 flew past Uranus and observed radiation levels that defied explanation. Now, scientists may finally know exactly what happened.

Only certain types of brain-training exercises reduce dementia risk, large trial reveals

By Kamal Nahas published

A large, 20-year trial showed that speedy cognitive exercises could reduce the risk of Alzheimer's disease and other types of dementia. The question is, could these tasks be adapted into video games?

Scientists infiltrated volunteers' dreams to boost their creative thinking

By RJ Mackenzie published

A small study hints that you can "trigger" memories of specific puzzles while a person dreams and that the dreamer may be more likely to solve the puzzle the next day.

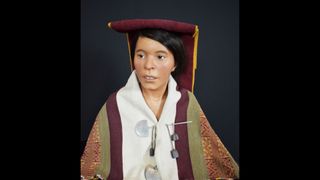

CT scans reveal the last moments of Inca children sacrificed as 'messengers to the gods'

By Tom Metcalfe published

New CT scans reveal the last moments of the Inca children who were sacrificed and mummified about 500 years ago.

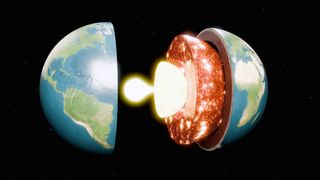

The largest reservoir of hydrogen on Earth may be hiding in its core

By Sascha Pare published

Earth's core contains nine to 45 times more hydrogen than the planet's oceans do, according to a new study that could settle a debate about when and how hydrogen was delivered to Earth.

Viking Age mass grave holds mysterious mix of dismembered human remains and complete skeletons, including a 'giant' who'd had brain surgery

By Kristina Killgrove published

Archaeologists and student excavators uncovered a Viking Age pit full of dismembered remains near Cambridge, England.

New 'sungrazing' comet could become visible to the naked eye during the day — if the sun doesn't destroy it

By Harry Baker published

The newly discovered sungrazing comet C/2026 A1 (MAPS) will undergo an extremely close slingshot around our star in early April, and could become bright enough to be seen without a telescope during the day.

Impossibly powerful 'ghost particle' that hit Earth may have come from an exploding black hole

By Harry Baker published

A supercharged neutrino that smashed into our planet in 2023 may have been spit out by an exploding primordial black hole with a "dark charge." If true, this theory could lead to a definitive catalog of all subatomic particles and unveil the elusive identity of dark matter.

Paleo-Inuit people braved icy seas to reach remote Greenland islands 4,500 years ago, archaeologists discover

By Kristina Killgrove published

Archaeological remains on the Kitsissut islands off the coast of Greenland reveal that whole communities regularly journeyed across the dangerous Arctic waters.

'Night owls' may have worse heart health — but why?

By Isha Ishtiaq published

Emerging evidence suggests that "night owls" are more likely to have poor heart health and a higher risk of heart attack or stroke than "morning larks." Why is that?

Microbes in Iceland are hoarding nitrogen, and that's mucking up the nutrient cycle

By Javier Barbuzano, Eos.org published

A study in Iceland found that microbes are hoarding more nitrogen for themselves, altering nutrient cycling and leaving less for plants.

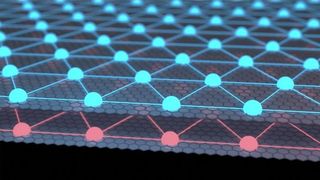

Physicists push quantum boundaries by turning a superfluid into a supersolid — and back — for the first time

By Damien Pine published

Physicists saw excitons, a type of quasiparticle, undergo a reversible phase transition from superfluid to supersolid for the first time, opening new doors for studying extreme states of matter.

Dramatic death of Comet C/2025 K1 (ATLAS) caught on camera — Space photo of the week

By Jamie Carter published

The Gemini North telescope snapped a spectacular view of Comet C/2025 K1 (ATLAS) breaking apart as it emerged from the other side of the sun in October.

AI-supported breast cancer screening spots more cancers earlier, landmark trial finds

By Jennifer Zieba published

A clinical trial shows that AI-assisted mammography can detect more cases of dangerous cancer and reduce missed diagnoses.

'There's no reason to ban us from playing': Analysis debunks notion that transgender women have inherent physical advantages in sports

By Kristina Killgrove, Nicoletta Lanese published

A meta-analysis of 52 studies that included over 5,000 transgender people suggests that transgender women's physical fitness after hormone therapy is comparable to that of cisgender women.

Clean energy is surging — with or without Trump

By Yale Climate Connections, Barbara Grady published

In 2025, solar and wind surpassed coal as a global energy source.

Discoveries inside Earth, Artemis II scrub, and an ape that can play pretend

By Ben Turner published

Science news this week Feb. 7, 2026: Our weekly roundup of the latest science in the news, as well as a few fascinating articles to keep you entertained over the weekend.

Get the world’s most fascinating discoveries delivered straight to your inbox.

Live Science Plus

Live Science Plus