How 3D Printing Will Transform Chinese Manufacturing (Op-Ed)

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

Melba Kurman, author, and Hod Lipson, Cornell University associate professor in mechanical and aerospace engineering, are co-authors of "Fabricated: the new world of 3D printing" (John Wiley & Sons, 2013) and leading voices in the field of 3D printing. They contributed this article to LiveScience's Expert Voices: Op-Ed & Insights as part of their new LiveScience series highlighting issues and developments in 3D-printing technology.

Compared to the United States and Europe, China has gotten off to a slow start as a 3D-printing powerhouse. But that's going to change rapidly.

On a recent book tour in China, we witnessed first-hand how 3D printing (pronounced like "san D da eeng" in Chinese) is igniting people's imaginations. Recently, Chinese astronauts sat in 3D-printed seats on their historic space flight. Each printed seat was tailored specially for that particular astronaut’s unique size and shape. On the industrial front, China is now home to seven 3D printer manufacturers, including a consumer-level model called the UP!. And, United States-based Stratasys (the largest 3D printer company in the world) employs about 150 employees in its Hong Kong office and plans to open an office in Beijing.

Not everyone in China has embraced the potential of 3D-printing technologies. Terry Gou, the high-profile chairman of Foxconn, has been an outspoken skeptic of the notion that 3D printing will trigger a new industrial revolution. Gou created a media buzz recently when he told reporters that "3D printing is a gimmick. If it really is that good, then I'll write my surname 'Gou' backwards." In Chinese culture, offering to re-arrange the spelling of your family name is a bold statement.

Gou makes a valid point. China's 3D-printing industry won't replace factories and mass production. In fact, if anyone doubts that mass manufacturing is here to stay, they need only to watch an industrial robot in action.

In Beijing, we wandered into a manufacturing trade show right next door to a 3D printing conference. Gou would have enjoyed the demos of state-of-the-art, robotic, high-speed mass-manufacturing machines. A few yards away from a meeting of experts speaking about the next industrial revolution and 3D printing, on the trade show floor we watched industrial robots pick, place and assemble parts so quickly that in comparison, a human worker would seem sluggish — not to mention an even slower-moving 3D printer. (See video clips.)

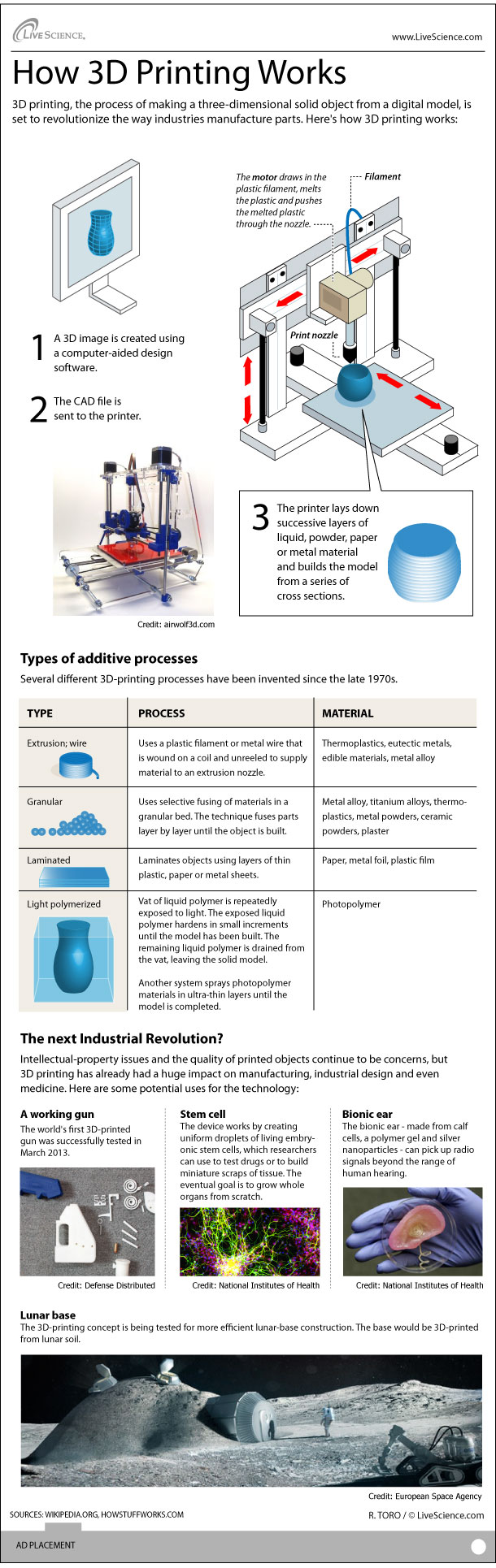

In the short term, 3D printing won't make a dent in China's mass production empire. In China, as in the United States, mass-produced commodity goods — where yours is the same as everyone else's and that's ok — will always be made using traditional factory machines. Instead, 3D-printing technology will serve as a catalyst to ease China's evolution into providing high-tech manufacturing and related services. [3D Printing: What a 3D Printer Is and How It Works]

Get the world’s most fascinating discoveries delivered straight to your inbox.

3D-printed products will continue to creep into the medical, dental and aerospace industries where customers are willing to pay a premium for custom products. In industries that aren't built on "markets of one," 3D printing will help product designers accelerate the design process. In fact, the consumer electronics industry has been, and will continue to be, one of heaviest users of 3D printing to test out and refine product design concepts. And that's no gimmick, Mr. Gou. [10 Amazing 3D-Printing Startups]

Moving toward higher-tech manufacturing

To understand the excitement about 3D printing in China, it helps to look at the nation's 12th (and current) Five-Year Plan. The Chinese economy is centrally steered by the government, which sets broad goals for the nation every five years. Over the next five years, China intends to evolve from being "the factory for the world" into a knowledge-driven economy based on innovative products and processes. [Autonomous Drones: Not Just Military Tech Anymore | Video]

Here are some of the key goals from the Five-Year Plan that relate to 3D printing:

– Maintain a strong mass-manufacturing base, but move up the value chain to high-margin, skilled-labor products in biotech, new materials, IT and specialized, high-end manufacturing;

– Grow the research and development (R&D) base and invest in universities;

– Develop the biotechnology and medical-device industries and expand high-end equipment manufacturing, in particular for aerospace and telecommunications equipment; and

– Reduce growing income disparities between low-wage, unskilled workers and China's growing middle- and upper-classes.

The advantages of a large domestic population

Looking into the future, China's massive population will accelerate the adoption of 3D-printed manufacturing. China's huge domestic market of consumers is becoming more sophisticated in its tastes. This increasingly affluent consumer base will demand novel and custom products that require advanced engineering and manufacturing capabilities. [Dos and Don'ts for Doing Business in China]

The Chinese government is investing in higher education in anticipation of a shift to a higher-skilled manufacturing economy. China will soon face the same labor challenges the United States is already grappling with. By educating more of its population, the Chinese government hopes to mitigate the potentially devastating double impact of factory automation and jobs lost to even cheaper labor markets. The result is that China's skilled workforce is growing rapidly. The number of students entering and graduating from Chinese universities has skyrocketed — from 1.6 million new students in 1999 to 7.5 million in 2012 — according to the China National Bureau of Statistics.

University research-project teams at Chinese universities are equally well-resourced. A single research project in an engineering department at one of China's top universities might have 50 graduate students working on different nuances of the same problem. China boasts millions of new university graduates, a large consumer population and well-funded academic research. The result will be a tremendous amount of intellectual horsepower that will rapidly enrich the nation's scientific and industrial knowledge-base. [3D Printing: From Doodads To Prosthetic Hands | Video]

Yet, China also faces unique challenges. Chinese R&D and 3D-printer manufacturers still lag Western companies in the development of novel materials for 3D printing.

Another challenge will be open communication. The Internet is a key component of the quick innovation that characterizes digital manufacturing. Yet, the Chinese government still censors the Internet with a filtering system sometimes called the Great Firewall.

As the ingenuity of Chinese Internet users continues to grow, along with their determination to speak openly, the Chinese government has responded by increasing its efforts to crack down on Web-based dissent. Governmental censors stifle the rapid spread of new ideas that come from the collective buzz of Twitter, YouTube, Facebook, Google News and Web searches.

Another challenge that's perhaps not unique to China is the fact that mass manufacturing supply chains won't be suitable for 3D-printed manufacturing. Mass manufacturers use centrally controlled, or what some describe as "monolithic supply chains," to produce commodity products. Such a centrally managed approach won't work well as highly specialized 3D-printed parts begin to play an increasing role in mass-produced products.

In the future, as manufacturing companies begin attempting to introduce small of batches of custom-made 3D-printed parts into their traditional supply chains, precise, responsive inventory management will become critical. An operational strategy that's suitable for making millions of simple and identical toasters won't be able to keep track of 3D-printed components for complex end-products

Finally, to deeply integrate 3D-printing technology into its design and manufacturing processes, China will need to aggressively re-think its intellectual-property laws. Change may be afoot, however. In anticipation of China's evolution from a mostly factory-based economy to one built on high-end manufacturing and knowledge work, the Chinese government is starting to tighten its intellectual-property laws. Global management consulting firm McKinsey & Co. reports that in 2012, "The Chinese government ministry charged with prosecuting intellectual-property violations recently announced that it handled 2,347 cases in 2012, up almost 40 percent from 2011, and over those two years, resolved $2 billion in violations."

China's national agenda has its eyes firmly fixed on building a knowledge-based economy where 3D-printing technologies will play a vital role. Chinese culture values self-discipline, hard work and respect for authority, beliefs that have enabled China to rapidly transform into the world's largest economy. It will be interesting to see China's factory for the world put 3D-printing technologies to work.

Live Science Plus

Live Science Plus