How 3D Printers Work (Infographic)

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

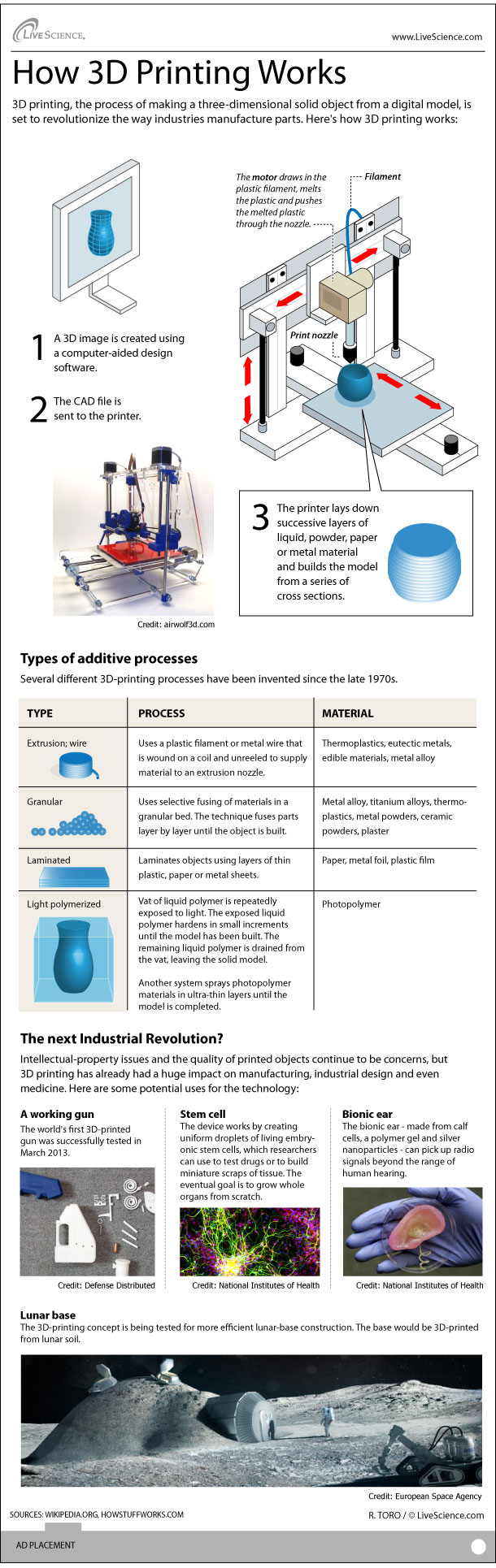

3D printing, the process of making a three-dimensional solid object from a digital model, is set to revolutionize the way industries manufacture parts.

First, a 3D image is created using a computer-aided design software (CAD). The CAD file is sent to the 3d printer.

The printer lays down successive layers of liquid, powder, paper or metal material and builds the model from a series of cross sections.

A motor draws a filament of plastic, melting the plastic and pushing the melted plastic through a nozzle.

Several different 3D-printing processes have been invented since the late 1970s.

The extrusion process uses a plastic filament or metal wire that is wound on a coil and unreeled to supply material to an extrusion nozzle. This process works with thermoplastics, eutectic metals, edible materials or metal alloy.

The granular process selectively fuses materials in a granular bed. Parts are fused layer by layer until the object is built. This process works with metal alloy, titanium alloys, thermo- plastics, metal powders, ceramic powders or plaster.

Get the world’s most fascinating discoveries delivered straight to your inbox.

The lamination process constructs objects from thin layers of plastic film, paper or metal foil.

In the light polymerization process, a vat of liquid polymer is repeatedly exposed to light. The exposed liquid polymer hardens in small increments until the model has been built. The remaining liquid polymer is drained from the vat, leaving the solid model. Another system sprays photopolymer materials in ultra-thin layers until the model is completed.

Live Science Plus

Live Science Plus