Amazon's new warehouse robot has a 'sense of touch' that could see it replace human workers

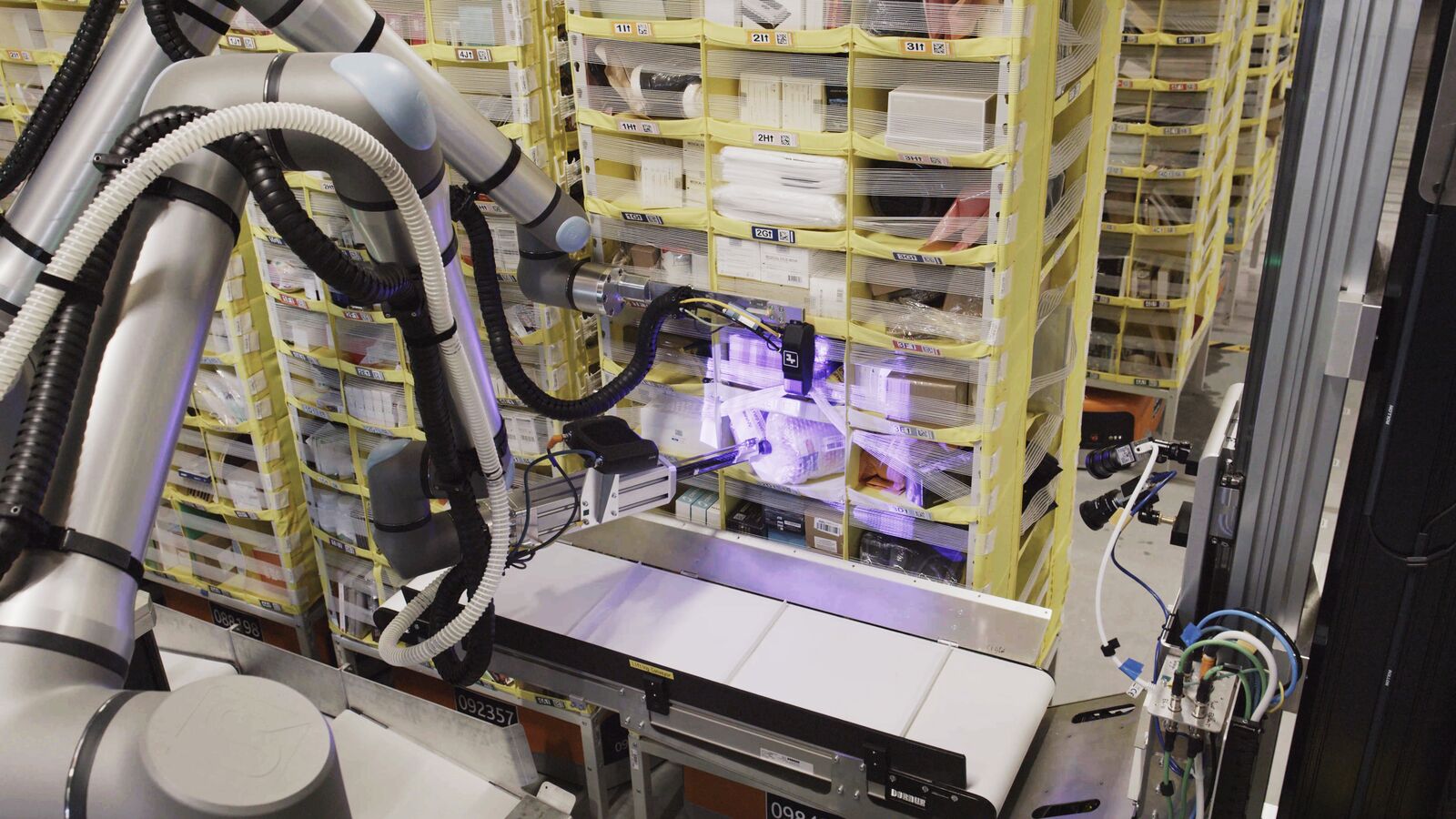

Amazon's Vulcan, the first warehouse robot with touch sensitivity, has begun operations in the company's Spokane, Washington, and Hamburg, Germany, fulfillment centers.

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

Amazon has announced a new robot with a sense of touch, enabling it to pick up and stow around three-quarters of the items found in its warehouses.

The new robot, called Vulcan, can accurately gauge the pressure required to grab and move warehouse items based on their size, dimensions and density, according to the e-commerce giant.

"Vulcan represents a fundamental leap forward in robotics," Aaron Parness, Amazon's director of applied science, said in a statement. "It's not just seeing the world, it's feeling it, enabling capabilities that were impossible for Amazon robots until now."

To achieve human-like touch sensitivity, Vulcan deploys a wand with both an item-identifying camera and a suction cup. Vulcan uses the wand to reach into warehouse stowing bins, move items around and identify the one it's searching for. This wand is at the end of a two-part robotic arm that can grip and pull items into or out of Amazon's inventory pods.

Related: Swarm of 30 robots can 'flow like water' and harden up to support the weight of a person

The wand's suction cup pulls items forward to the gripper, which functions as a conveyor belt to further move items in and out of bins. By feeding data into its artificial intelligence system, Vulcan learns from each item interaction and adjusts future engagements based on what it has learned. Vulcan can also sense when it can't move an item and can ask for human assistance.

Vulcan is currently in operation at Amazon's Spokane, Washington, and Hamburg, Germany, fulfillment centers.

Get the world’s most fascinating discoveries delivered straight to your inbox.

Boston Dynamics, Fetch Robotics (which was acquired by Zebra Technologies in 2021) and RightHand Robotics have all faced difficulties in training robots to mimic human levels of touch sensitivity. This is because robots would inaccurately identify the durability of items and either crush them or not apply enough pressure to grab and transport them properly, according to Parness.

Over the past 12 years, Amazon has deployed 750,000 robots in its warehouses across the globe — a number that nearly matches the company's 1 million human employees.

Amazon said that, in addition to improving efficiency, this robotic fleet will reduce the ergonomic stress of its warehouse employees by eliminating the need to use stepladders or bend down to reach items. The company also claims the scaling of Vulcan across its warehouses will create a new category of jobs for humans, including robotic floor managers and employees to oversee and ensure the quality of the robotic fulfilment of orders.

Yet Amazon has another ambition in mind for Vulcan and its robotic fleet: reducing the company's reliance on human labor. An internal document acquired by Business Insider said Amazon's robots are "critical to flattening Amazon's hiring curve over the next ten years" to save the company as much as $10 billion annually by 2030.

Lisa D Sparks is a freelance journalist for Live Science and an experienced editor and marketing professional with a background in journalism, content marketing, strategic development, project management, and process automation. She specializes in artificial intelligence (AI), robotics and electric vehicles (EVs) and battery technology, while she also holds expertise in the trends including semiconductors and data centers.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.

Live Science Plus

Live Science Plus