Curved Electronics Could Yield Eye-Like Digital Camera

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

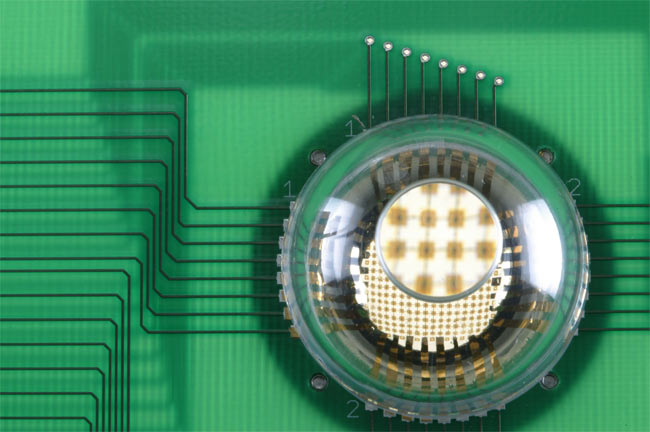

As if a human eye were popped into a camera, researchers have created a lens-shaped detector and placed it into a digital camera. The result, they say, could give the cameras a wider field of view and the capacity to produce crisper images.

The "electronic eye camera" relies on silicon detectors and electronics that can be shaped to a curved surface. Like the human eye, the curved light detectors act like our retina's rods and cones, which detect the incoming light and transfer it via the optic nerve to the brain where an image is formed.

"The retina is sort of on the back surface of your eyeball," said researcher John Rogers of the University of Illinois at Urbana-Champaign. "So in our cameras, we have a similar kind of eyeball that's made out of glass and our [silicon photo] detector sits on the surface of that hemispherical cavity in the same way that your rods and cones sit on the back surface of your eyeball."

Rogers expects the technology could show up in digital cameras within five to seven years.

The camera is just 256 pixels, but Rogers said the same approach should be feasible for systems with a lot more pixels. Currently, digital cameras can boast tens of Megapixels. Pixels represent the number of photo-detectors in digital cameras and can be thought of as a measure of the resolution of the pictures taken.

In a normal camera, the silicon photodectors are fitted to a flat silicon wafer, making it so the camera's lenses must reflect an image several times before it can reflect on the right spots on the flat focal plane. The resulting images are less sharp than what we see with our eyes.

Scientists have been stumped over how to place those electronics on a curved surface to yield working cameras, despite many different attempts over the last 20 years.

Get the world’s most fascinating discoveries delivered straight to your inbox.

Rogers, Yonggang Huang of Northwestern University in Evanston, Ill., and their colleagues made a thin, elastic membrane and stretched it out flat. They transferred the flat electronics onto the membrane and popped the membrane back into its curved shape.

Usually, this "popping back" leads to breaking of the brittle semiconductor materials.

So Rogers and Huang created a series of photodetectors and circuit elements that are so small they aren't affected when the membrane snaps back to a curved form. (Think of them like buildings on the Earth — though flat buildings are built on the curved Earth, the area they take up is so small that the curve isn't felt.)

They also connected each of the 256 silicon detectors (pixels) with thin plastic wires. (In normal cameras, metal is used as a connector.) The so-called pop-up bridges take the strain associated with the return of the membrane to its curved shape.

"So they can kind of move relative to one another," Rogers told LiveScience. "And those little plastic ribbon cables can deform in a way that doesn't lead to fracture."

The team incorporated the curved system into a working eye-like camera. The resulting images were much clearer than those obtained with similar, but flat, digital cameras.

The research, detailed in the Aug. 7 issue of the journal Nature, was funded by the U.S. Department of Energy, University of Illinois at Urbana-Champaign, National Science Foundation, Korea Research Foundation and the Beckman postdoctoral fellowship.

- 10 Technologies That Will Transform Your Life

- Innovations: Ideas and Technologies of the Future

- TechShop: Where Inventors' Dreams Are Made

Jeanna Bryner is managing editor of Scientific American. Previously she was editor in chief of Live Science and, prior to that, an editor at Scholastic's Science World magazine. Bryner has an English degree from Salisbury University, a master's degree in biogeochemistry and environmental sciences from the University of Maryland and a graduate science journalism degree from New York University. She has worked as a biologist in Florida, where she monitored wetlands and did field surveys for endangered species, including the gorgeous Florida Scrub Jay. She also received an ocean sciences journalism fellowship from the Woods Hole Oceanographic Institution. She is a firm believer that science is for everyone and that just about everything can be viewed through the lens of science.

Live Science Plus

Live Science Plus