New Technique Could Make 300-Carat Diamonds

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

Researchers have developed a new technique for making very large diamonds of high quality that could soon boost optics technology and gaudily adorn fingers of the wealthy with sparkling rocks up to an inch wide.

Using a process called chemical vapor deposition (CVD), several groups have figured out how to make diamonds. But growing them over 3 carats has proved challenging.

A carat is a unit of weight for gems.

"Our fabrication of 10-carat, half-inch, CVD diamonds is a major breakthrough," said Russell Hemley of the Carnegie Institution's Geophysical Laboratory. "We can make a 1/3 carat gems in one day."

The size is about five times what commercial diamond manufacturers can make using standard processes, Hemley and his colleagues said today.

In theory, the technique should be able to make diamonds an inch big, or roughly 300 carats.

The famed Hope Diamond is 45.52 carats.

Get the world’s most fascinating discoveries delivered straight to your inbox.

Natural diamonds, composed of carbon, are the hardest things known. They can be billions of years old, formed under intense pressure. Today, more diamonds are used in technology and industry than as adornment. They are superb for cutting and are even used in semiconductors.

Diamond is so hard it can be used to create pressure equal to the center of the Earth, a handy condition for testing theories of how substances react (hydrogen turns into a metal in such lab tests).

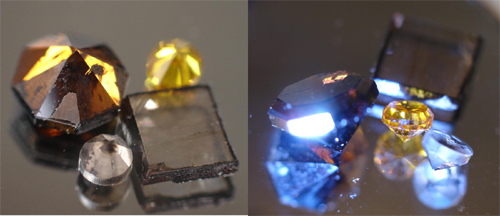

Natural diamonds can be clear or colored, depending on the presence of other materials in addition to carbon.

Synthetic diamonds are typically yellow or brown, limiting their use in optical technologies. Colorless diamonds -- a big goal for optics, scientific research and jewelry -- are expensive to make.

"Fundamentally there is no difference," Hemley told LiveScience. "Both have the same crystal structure. However, natural diamonds generally have many more defects."

The new process developed at Carnegie produces transparent diamonds, as well as some of striking color.

Hemley said the costs are low, but pricing at a jewelry store would depend on how synthetic gems are marketed.

"The diamond age is upon us," Hemley said.

Related Stories

- Hope Diamond Traced to French Crown

- Transparent Material Could Lead to Disposable Electronics

- Microscopic Diamond Found in Montana

- Diamond-Polished Stone Age

Try These on for Size

Carnegie Institution

Live Science Plus

Live Science Plus