What Are Rare Earth Elements?

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

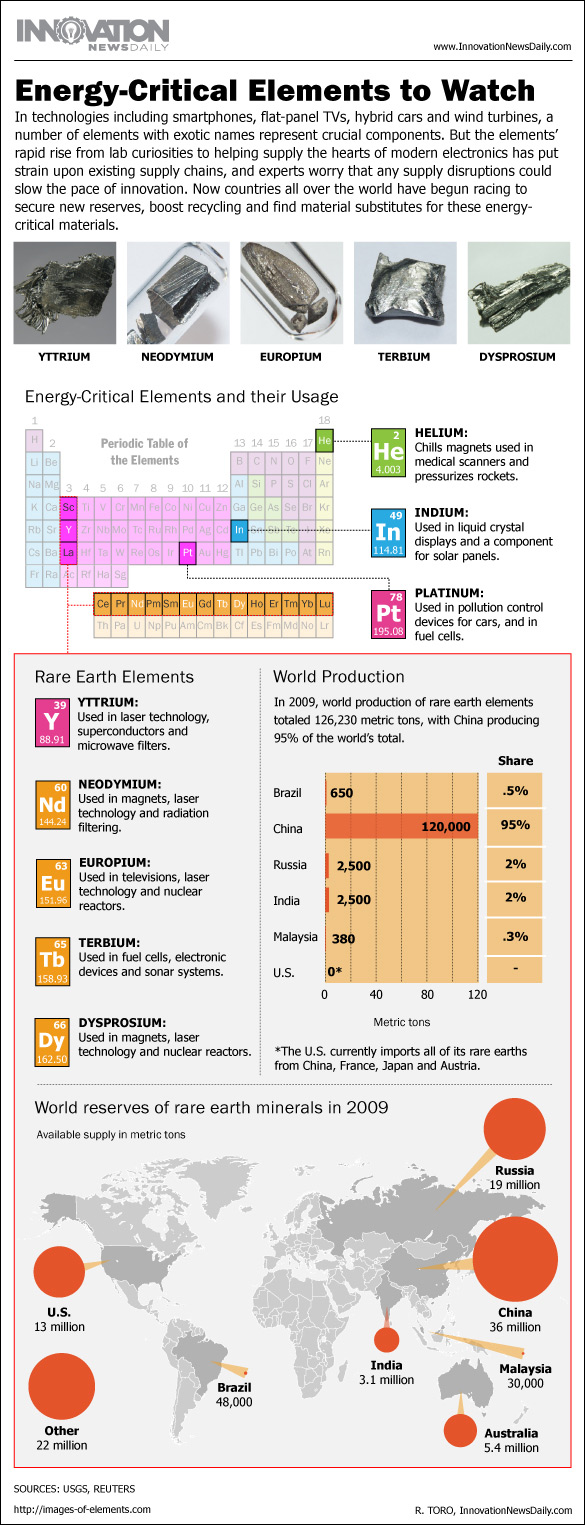

Rare earths – which include exotic-sounding elements like dysprosium, cerium, and ytterbium – are actually more abundant than other familiar metals, but tend to become concentrated in less exploitable ore deposits, according to the U.S. Geological Survey. Consequently, most of the world’s supply of these elements comes from only a few sources.

Mineral deposits reported to contain rare earth elements were discovered in Afghanistan in 2010. The deposits may be worth $1 trillion.

Consumers may not know that their computer hard drives, TV screens, and smartphones contain rare earth elements. The often-irreplaceable metals also support everything from green technologies to military hardware.

For example, europium makes the red color for television monitors and energy-efficient LED light bulbs, while neodymium makes some of the most powerful magnets found in everyday electronics, wind turbines and hybrid cars.

Light rare earth elements include the metals ranging from lanthanum to gadolinium on the periodic table of elements, while heavy rare earth metals range from terbium to lutetium.

So-called green technologies often depend upon rare earth elements. For instance, Toyota uses an estimated 7,500 tons of lanthanum and 1,000 tons of neodymium per year to build its Prius cars, according to Jack Lifton, an independent consultant who works with U.S. Rare Earths, a company that owns the rights to rare earth element resources in the U.S.

Rare earth minerals are just as crucial for military applications, such as lasers, radar, missile-guidance systems, satellites and aircraft electronics.

Get the world’s most fascinating discoveries delivered straight to your inbox.

China and the U.S. have some of the largest rare earth mineral deposits, but other deposits exist in countries such as Australia, Brazil, India, Malaysia, South Africa, Sri Lanka and Thailand, according to the USGS.

Mining is just the first step. Extracting the individual rare earth metals from the raw ore requires thousands of stainless steel tanks holding many chemical solutions, according to Jim Hedrick, a former USGS rare earth specialist. The overall refining process converts ore into oxides, and then converts the oxides into refined metals.

Only China currently has the equipment to refine rare earth metals from start to finish, and it supplies as much as 97 percent of the world's rare earth oxides. Opening one mine and building a separation plant might cost anywhere from $500 million to $1 billion, Hedrick said.

Related:

Live Science Plus

Live Science Plus