Navy's Secret to Building a Stealth Ship (Op-Ed)

Get the world’s most fascinating discoveries delivered straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered Daily

Daily Newsletter

Sign up for the latest discoveries, groundbreaking research and fascinating breakthroughs that impact you and the wider world direct to your inbox.

Once a week

Life's Little Mysteries

Feed your curiosity with an exclusive mystery every week, solved with science and delivered direct to your inbox before it's seen anywhere else.

Once a week

How It Works

Sign up to our free science & technology newsletter for your weekly fix of fascinating articles, quick quizzes, amazing images, and more

Delivered daily

Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Join the club

Get full access to premium articles, exclusive features and a growing list of member rewards.

Nikhil Gupta is an associate professor and Steven Zeltmann is a student researcher in the Composite Materials and Mechanics Laboratoryof the Mechanical and Aerospace Engineering Department at New York University's Polytechnic School of Engineering. Gupta and Zeltmann contributed this article to LiveScience's Expert Voices: Op-Ed & Insights.

The USS Zumwalt, the United States Navy's latest and largest destroyer, is a stark contrast to the ironclad ships of old. The gray angular deckhouse may bring back memories of Civil War-era battleships, but the technology of the deckhouse and what lies inside is anything but old-fashioned.

The Zumwalt, or DDG-1000, is the first of three ships of the Zumwalt class to be completed. This project is a huge undertaking by the U.S. Navy and represents the single largest line item in its budget. But the new technologies being developed as part of the program will make the Zumwalt class years ahead of any other current warship — one profound example is the deckhouse material.

The Zumwalt makes extensive use of composite materials in the deckhouse structure — not only to make the structure lighter, but also to control the ship's radar profile and achieve a high level of stealth.

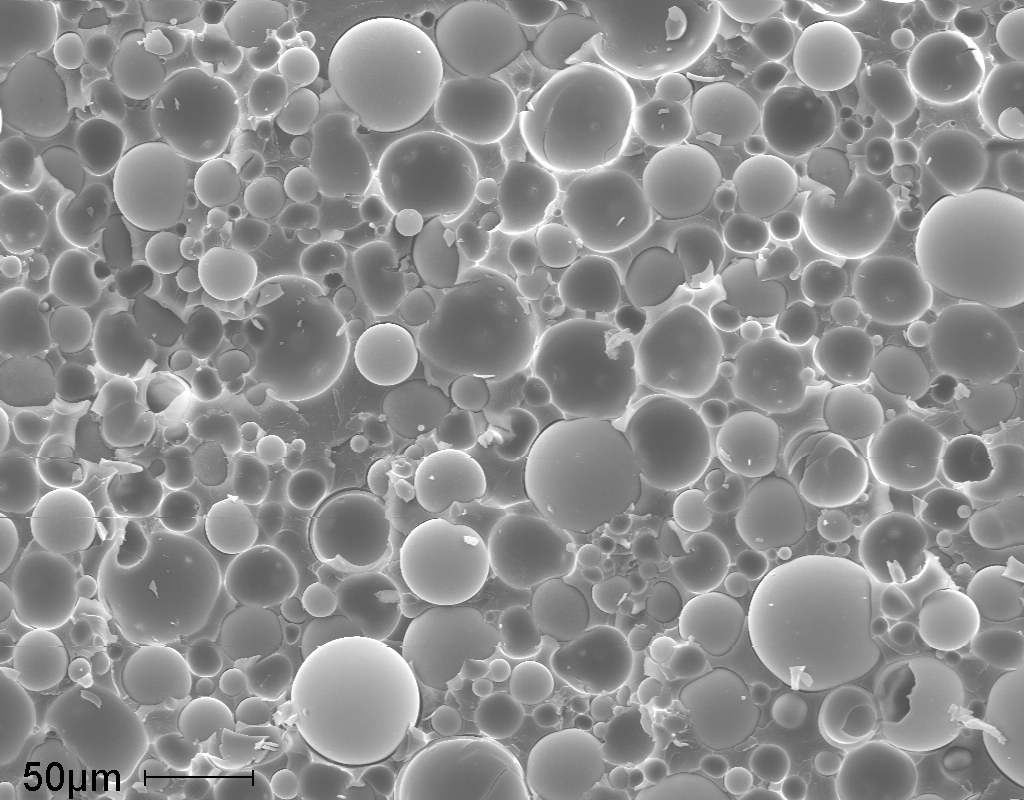

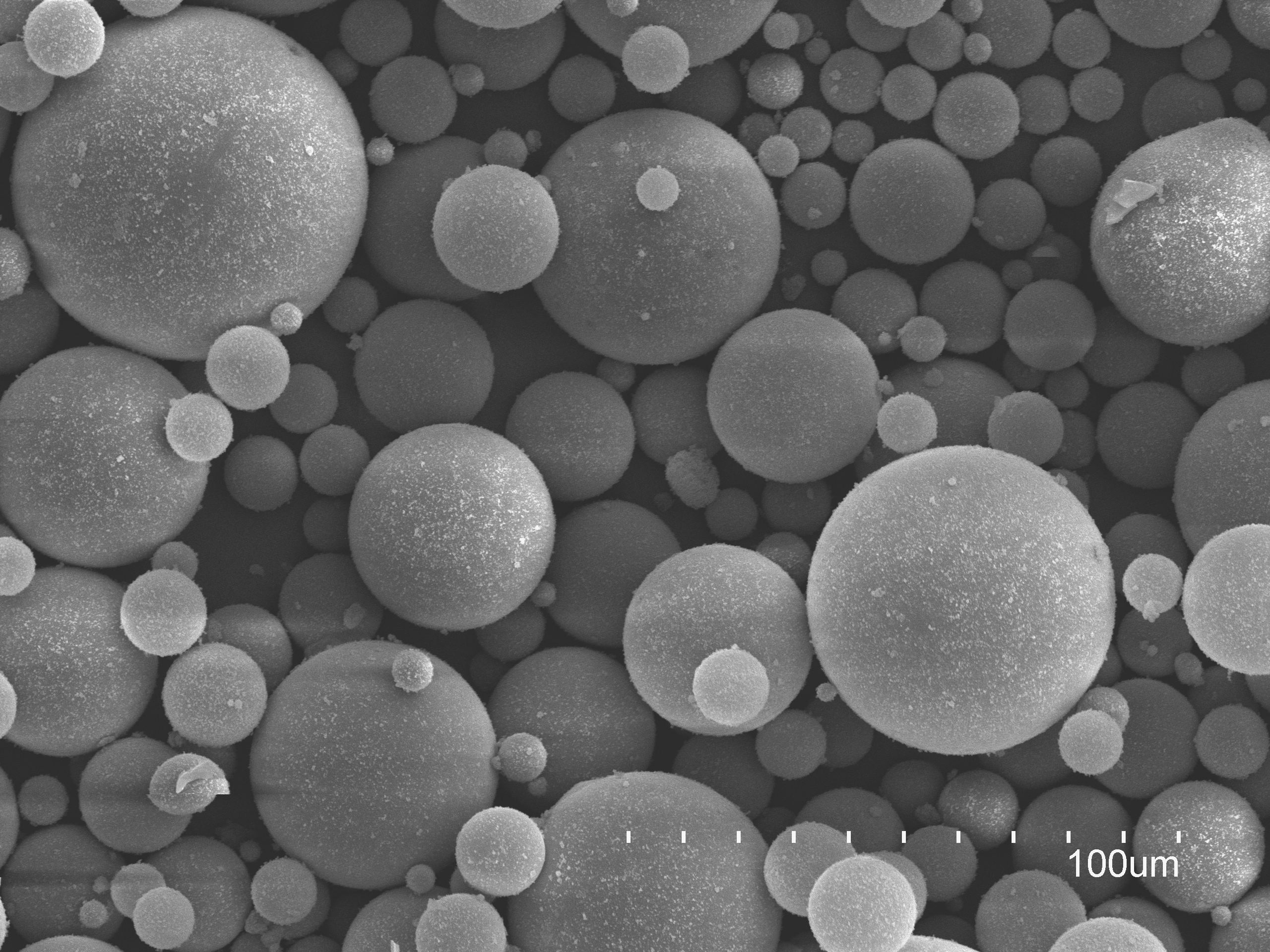

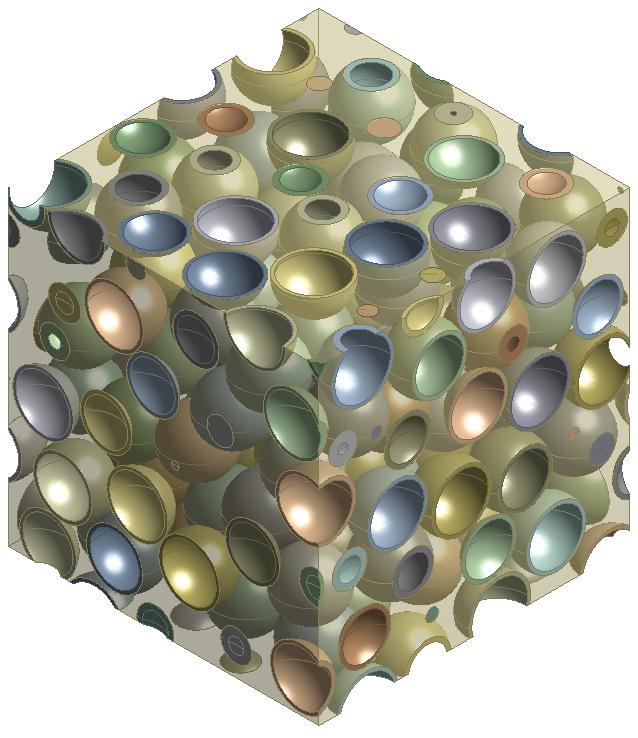

One of the most important and advanced composites used in the deckhouse is a material known as syntactic foam, which incorporates hollow particles that entrap air in a polymer. The hollow particles are microscopic, sometimes as small as 10 microns (about one-tenth the thickness of a human hair), and made of stiff materials like glass. The hollow, particle-filled polymer composite of the Zumwalt's deckhouse acts like a lightweight sponge, but one that doesn't absorb water because the pores are enclosed inside the glass particles. The glass shell of the particles also reinforces the voids, and creates a material that is lightweight, but strong.

Syntactic foams have already seen widespread use in civilian and commercial deep-sea vehicles, including the remote-operated submersible currently being used in the search for MH370, or the Challenger craft used by James Cameron in the solo dive to the deepest part of the ocean. This is because syntactic foams overcome two of the major disadvantages of traditional polymer foams: low stiffness and high water absorption. [Finding the Strength to Reach the Ocean's Furthest Depths]

But in the Zumwalt, the choice of syntactic foam was not based just on its light weight and low water absorption. The ship makes use of one other unique property of syntactic foam: its highly tailorable radio-transmission characteristics. The Zumwalt uses more than 3,500 cubic feet of syntactic foam to achieve the radar profile of a small fishing boat, despite being the largest destroyer in the Navy's fleet. The syntactic foams used in much of the deckhouse are designed to absorb and attenuate radar signals rather than reflect them, thereby confusing the enemy's tracking systems.

Get the world’s most fascinating discoveries delivered straight to your inbox.

It's easy to notice that the complex radar and antenna structure common to all Navy ship decks is absent on the Zumwalt. The antennae are enclosed within the ship's "invisible" syntactic-foam deckhouse. The foam is designed to transmit the signals from the ship's own radar systems, but instead of having a complex shape on the exterior of the ship — which is easy to spot on radar — the clean-slab sides mask the profile of the antennae from enemy radar.

Research on syntactic foams and other advanced functional materials is essential to keeping the U.S. naval fleet ahead of the competition. Our lab works closely with the Navy to develop new materials and to gain a greater understanding of how the existing materials function at the microscopic level. We're also exploring how nanoscale fillers, like carbon nanofiber in syntactic foams,might improve the materials' strength and electromagnetic radiation interference signatures —possibly for use in the next generation of advanced ships.

Follow all of the Expert Voices issues and debates — and become part of the discussion — on Facebook, Twitterand Google +. The views expressed are those of the author and do not necessarily reflect the views of the publisher. This version of the article was originally published on LiveScience.com.

Live Science Plus

Live Science Plus