Carbon Nanofiber Makes Smart Yarn

Science fiction writer Neal Stephenson wrote about arachnofiber uniforms in his 1992 novel Snow Crash. These bulletproof and lightweight uniforms were worn by the Deliverators, the world's best pizza delivery guys. Carbon nanofiber can now be spun like yarn to make an amazing variety of new inventions possible, including lightweight bulletproof uniforms.

Among the many possibilities:

- Soft protective vests stronger than Kevlar

- Bandages that can contract to put pressure on

- Artificial muscles powered by electricity - much lighter than current hydraulics

- Would make it easier to incorporate electronic sensors and actuators into clothing.

All of these possible applications derive from the remarkable properties of carbon nanotubes; the ability to conduct both heat and electricity along with the extreme toughness of the fiber.

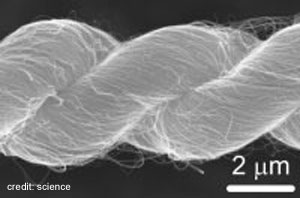

The researchers created the yarn by growing a mat of fibres on a substrate, called a nanotube forest. A sharp, pointed instrument then pulled at the fibres along the plane of the substrate.

Atkinson said the tubes then formed into a "conga line" and were twisted and wrapped around each other as they were pulled. "As long as there are fibres in the forest, you can make a yarn as long as you want. You get a very even strand," he said. "People say how can you spin something that is one-third of a millimetre long, but it is the length-to-diameter ratio that matters. We use fibres with a 10 nanometre diameter and put in a lot of wraps."

If you are interested in how technology is producing science-fictional clothing, take a look at Scentsory Chameleon Bodysuit: Biometric Fashion. Bulletproof vests and body armor tends to be rigid - but not Liquid Body Armor in Two Flavors - Shear Thickening and Magnetorheological.

(This Science Fiction in the News story used with permission from Technovelgy.com - where science meets fiction.)

Get the world’s most fascinating discoveries delivered straight to your inbox.