Wearable Electronics Pave Way for Smart Surgeon Gloves

New wearable electronics could become smart surgical gloves that allow surgeons to feel and do everything using their fingertips. Such electronics could even include electronic "socks" wrapped snugly around a patient's heart to monitor cardiac health.

The idea of stretchy smart materials fitting the hands of surgeons or human hearts comes from researchers who have discovered how to transform hard semiconductors into soft, flexible electronics. A U.S.-China team has published its blueprint for designing and making smart devices that can wrap around 3D objects like the human fingertip.

"The biggest challenge is in integrating a hard, brittle material like silicon, which exists for high performance electronics only in the form of planar, rigid wafers, into a thin, stretchable skinlike system that has a 3D curvature like the body," said John Rogers, a materials engineer at the University of Illinois at Urbana-Champaign.

Rogers and his colleagues from the University of Illinois, Northwestern University and China's Dalian University of Technology have already built and tested the form-fitting cardiac "socks." Such smart materials could someday lead to medical gloves that not only give a heightened sense of touch, but also allow surgeons to "feel'' the electric activity related to heart health and behavior.

Advanced versions of the smart surgical gloves could even allow surgeons to precisely remove or cut heart tissue during surgery with a touch of their fingertips, Rogers said. [Smart Clothing Could Become Wearable Gadgets]

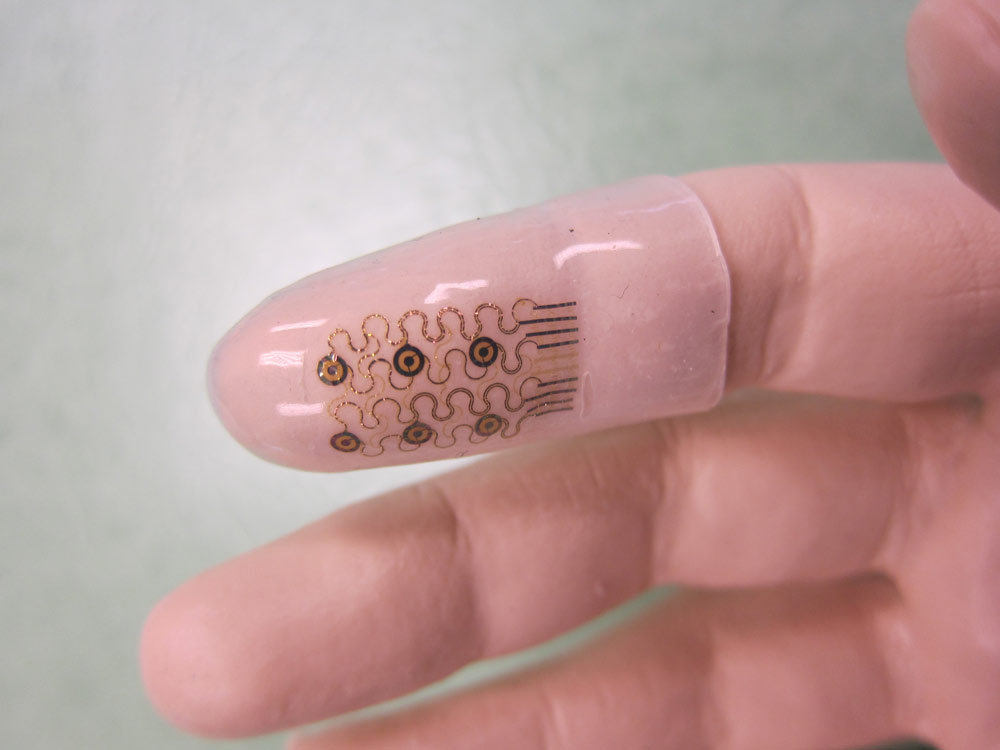

The researchers achieved their flexible breakthrough by making silicon into ultrathin "nanomembranes" that are about 10,000 times thinner than the width of a human hair. They then cut the nanomembranes into wavy snakelike shapes and combined them with a thin rubbery membrane that allowed the entire material to "stretch, twist, bend and wrap curved surfaces" without damaging the silicon.

"One doesn't need to break any laws of physics to make this happen," Rogers told InnovationNewsDaily. "The challenges are now less in concepts and more in engineering execution."

Get the world’s most fascinating discoveries delivered straight to your inbox.

The flexible silicon was printed on the outside of elastic "finger-tubes," so that researchers could simply flip the finger-tubes inside out to have the electronics touching the wearer's skin. The electronics included stimulators capable of transmitting information to humans as a tingly sensation or vibration and sensors that could measure the pressure of physical contact.

Other electronics included "strain gauges" attached to the lower part of the hand that could detect the stretching sensation of the wearer moving his or her finger. The researchers published their paper in the Aug. 10 issue of the journal Nanotechnology, and have already begun creating wearable electronics through their startup company called MC10.

Additional testing with a more diverse array of flexible electronics could also lead to devices that monitor human body temperature and hydration level. Such health and wellness monitoring capabilities could benefit an MC10 joint project with sportswear company Reebok — a project that may unveil commercial products before the end of 2012.

This story was provided by InnovationNewsDaily, a sister site to LiveScience. You can follow InnovationNewsDaily Senior Writer Jeremy Hsu on Twitter @ScienceHsu. Follow InnovationNewsDaily on Twitter @News_Innovation, or on Facebook.