Sweatin' the Small Stuff, What Mechanical Engineering Is About

This ScienceLives article was provided to LiveScience in partnership with the National Science Foundation.

Kira Barton sweats the small stuff. A mechanical engineer at the University of Michigan at Ann Arbor, Barton works on next-generation manufacturing processes — at the smaller-than-tiny scale.

Her research supports the manufacture of everything from high-resolution, DNA-detecting sensors to sophisticated robots. It is part of a national effort in advanced manufacturing to develop new technologies that will dramatically reduce the time required to design, build and test goods. Those advances are already happening. The screen right in front of you, for example, was made with the type of meticulously developed techniques Barton and others in the advanced manufacturing field make possible.

Below, Barton talks about her life and work as a researcher.

Name: Kira Barton Age: 35 Institution: University of Michigan Hometown: Silverthorne, Colorado (original); Ann Arbor, Michigan (current) Field of study: Mechanical engineering

Why did you choose your field of research?

I'd always been leaning toward math and science, and into building things with my hands. In graduate school I was fortunate to work in a National Science Foundation (NSF)-sponsored center at the University of Illinois (Nano-CEMMS), where I got to work on a diverse team with a range of backgrounds.

Get the world’s most fascinating discoveries delivered straight to your inbox.

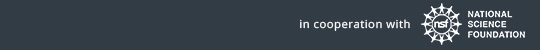

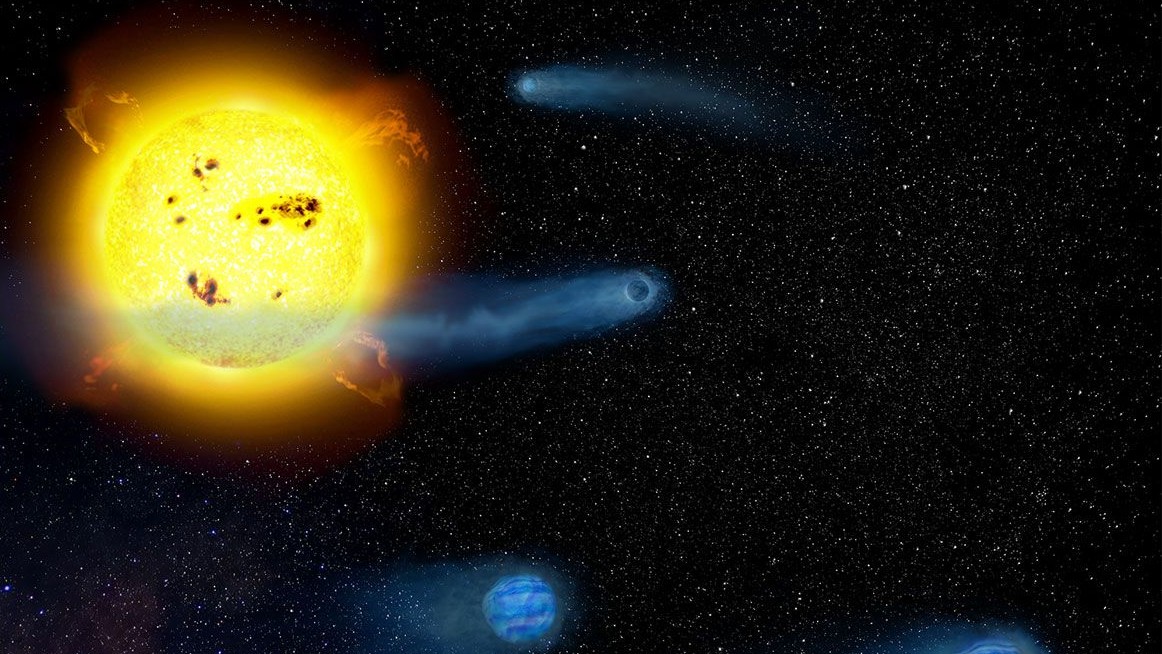

I learned about all the cool, new things being developed. For example, technology that can print with electronic or biologic materials, creating flexible electronics or sensors at the micro and nano-scales.

What was the best professional advice you ever received?

To go and find things you can really be passionate about. When you find areas that are exciting and the work and people are interesting, it doesn't feel like work. It's fun. My PhD advisor gave me that advice.

What are you most proud of?

Right now, I'm most proud when I see the accomplishments of the next generation. When you see a student's light bulb go off or spark of curiosity in labs and classrooms, it's a really good feeling.

What was your biggest laboratory disaster, and how did you deal with it?

Any time you have a person interested in your work come to visit, that's when everything suddenly stops working. It's almost as if there is a scientific law stating that the moment when you need something to work, that's when it fails.

For example, we had a big site visit at an NSF center with lots of important people. We spent weeks preparing. The first run out, our demonstration breaks. But that's when you keep your cool and say, "This is how research works. Let me show you what we meant to have happen."

You have to anticipate moments like that because they occur all the time.

What is the biggest challenge you are facing right now?

Given the economic climate, funding is always a challenge. The biggest challenge is finding the right resources to keep your lab running — to support the students in your lab to focus on research that needs to be done.

What would surprise people most about your work?

People have a preconceived idea of what manufacturing is. But if you look at my work, you would be surprised at the diversity of research topics within manufacturing. There are biologists, chemists, materials scientists — all sorts of people with different expertise and backgrounds.

From my perspective, manufacturing is becoming more high-value, where we're looking at coming up with completely new technologies and products. New ways of pushing the envelope.

By high-value, I mean lighter materials, improved functionality, essentially finding ways to enable capabilities people want.

One example would be flexible electronics, like last year's electronic circuit printed into a DIY tattoo that measures heart rate and temperature. Ideas that completely change your idea of what it means to have a sensor hooked up to you. That has advantages for kids; they won't pull the sensor off. You can put it into a blanket or clothing. Yet, you still collect data. I think you're going to see a lot more, from cell phones to sensors printed into clothing.

Who is your biggest hero and why?

My sister. My older sister is a scientist, a professor in biology. Her passion for what she does really has inspired me throughout my life.

What advice would you give to an aspiring engineer or scientist?

To be curious. Be curious about what topics or areas you find of interest, and encourage and develop that curiosity. That's what drives science: to seek knowledge, to ask the question and go that next step.

Have you ever been surprised by the results of an experiment?

Yes, of course. One time I was a grad student working on a printing process that was relatively new. It was a relatively slow process to ensure consistency. We made a small modification and it made three to four orders of magnitude difference. That level of improvement was surprising. And it surprised everyone because it was relatively straightforward. That was a reminder you don't always need big complicated solutions to have big fixes.

Why should my [mom, kid sister, grandpa] be excited about your research?

Manufacturing is part of everything. All products we have on a daily basis come from manufacturing. That ability to design, to create a new concept, then go and make it, is engineering and manufacturing. And it's fun.

I can see that in my two-year-old daughter. I watch her get excited when she builds or creates something.

And that's what we do. We build. We create. You sit down in your house and everything in your house was designed and manufactured to do what you want.

Editor's Note: The researchers depicted in ScienceLives articles have been supported by the National Science Foundation, the federal agency charged with funding basic research and education across all fields of science and engineering. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author and do not necessarily reflect the views of the National Science Foundation. See the ScienceLives archive.

Live Science Plus

Live Science Plus