Spider's Silk Strands Work Together to Keep Web Intact

A spider web gets its strength from silk strands working together and their ability to stretch when stressed, new research suggests.

Out in the wild world, webs need to deal with different types of stress: winds, which blow the whole web at once, and items such as falling tree debris or struggling bugs that may stress only a few strands of silk. Researchers from the Massachusetts Institute of Technology and Nicola Pugno of the Polytechnic University of Turin, in Italy, wanted to figure out how spider webs stay whole under these various stresses.

When the spiders make their webs, they use two kinds of silk. The non-sticky dragline silk is used to make the spokes radiating out from the center, while the sticky and stretchy viscid silk swirls outward in a circular fashion and is used to catch the spider's prey. The two silk types have different structures, purposes and properties under stress.

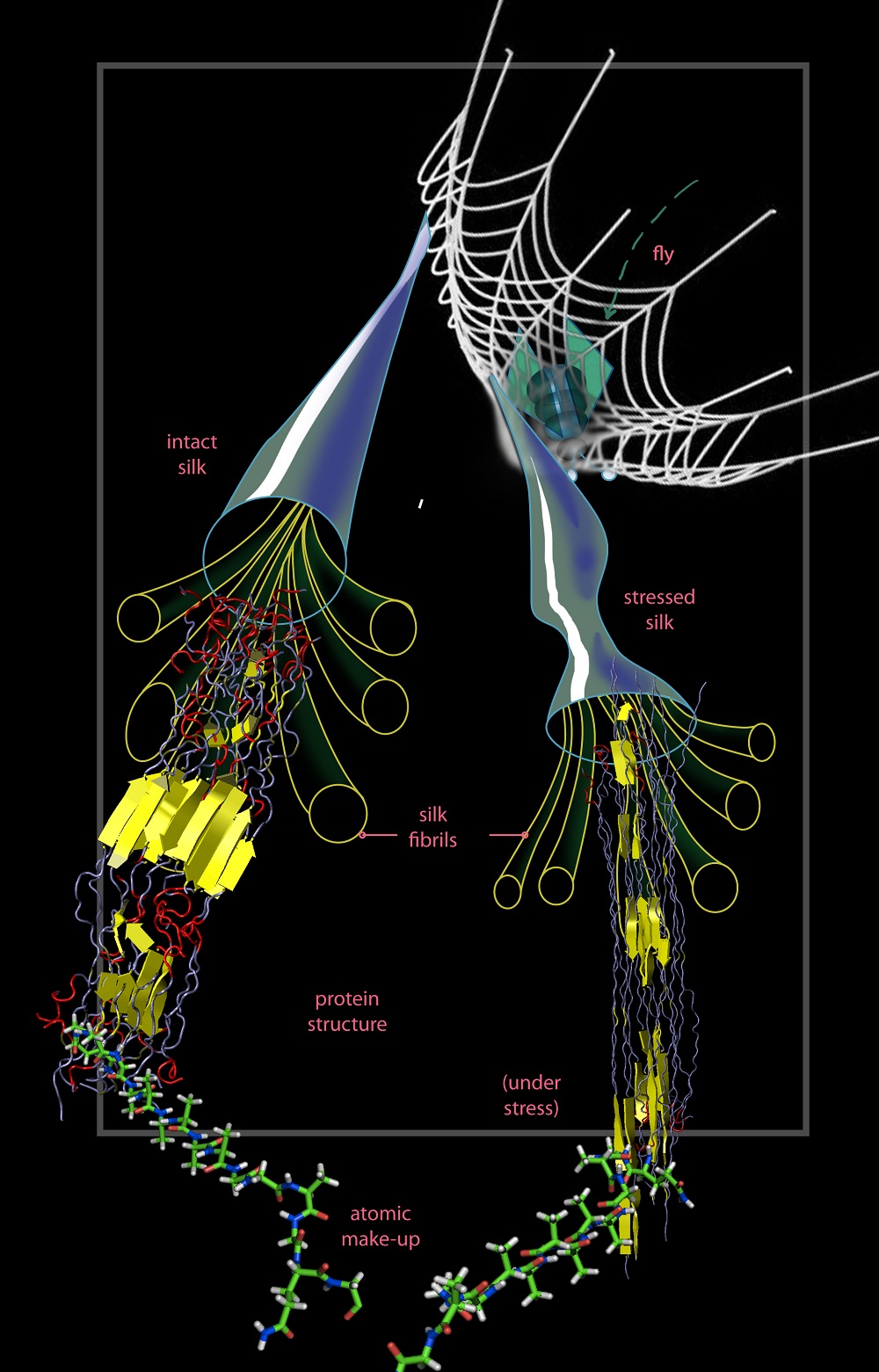

"Multiple research groups have investigated the complex, hierarchical structure of spider silk and its amazing strength, extensibility and toughness," study researcher Markus Buehler said. "But while we understand the peculiar behavior of dragline silk from the 'nanoscale up' — initially stiff, then softening, then stiffening again — we have little insight into how the molecular structure of silk uniquely improves the performance of a web."

The researchers tested natural webs in the lab and the field, then used this data, along with information from other studies of spider silk properties, to make an intricate model of a spider's web.

They found that the spider silk's unique molecular structure unfurls with the increasing stress of being pulled, producing a stretching effect that's good for catching prey. It has four distinct phases: an initial, linear tugging; a drawn-out stretching as the spiders silk proteins unfold; a stiffening phase that absorbs the greatest amount of force; and then a final, stick-slip phase before the silk reaches the breaking point.

"We scaled up the molecular behavior of silk threads to the macroscopic world," study researcher Anna Tarakanova said. "This allowed us to investigate different load cases on the web, but more importantly, it also allowed us to trace and visualize how the web fractured under extreme loading conditions."

Get the world’s most fascinating discoveries delivered straight to your inbox.

When the web is lightly stressed, like with a light wind, the silk only reaches the point where it softens and extends. But when the web is under heavy stress, especially when the stress is localized to one area, the researchers found that a few strands might break, but this sacrifice leaves the rest of the web intact.

Building a stronger web

"Engineered structures are typically designed to withstand large loads with limited damage — but extreme loads [like hurricane winds] are more difficult to account for," study researcher Steven Cranford said. "The spider has uniquely solved this problem by allowing a sacrificial member to fail under high load."

It is an important feature, because if the web were to unravel at the slightest break, the spider wouldn't have the energy to keep rebuilding it.

Spider-web researcher Todd Blackledge, of the University of Akron in Ohio, is also studying how webs deal with stress, though he wasn't involved in this study. "My lab concentrates on a 'top-down' approach using high-speed video and material property testing of silks from real webs to assess how energy is absorbed by orb webs under 'hard' versus 'easy' impacts," Blackledge told LiveScience in an email. "We've come to several similar conclusions."

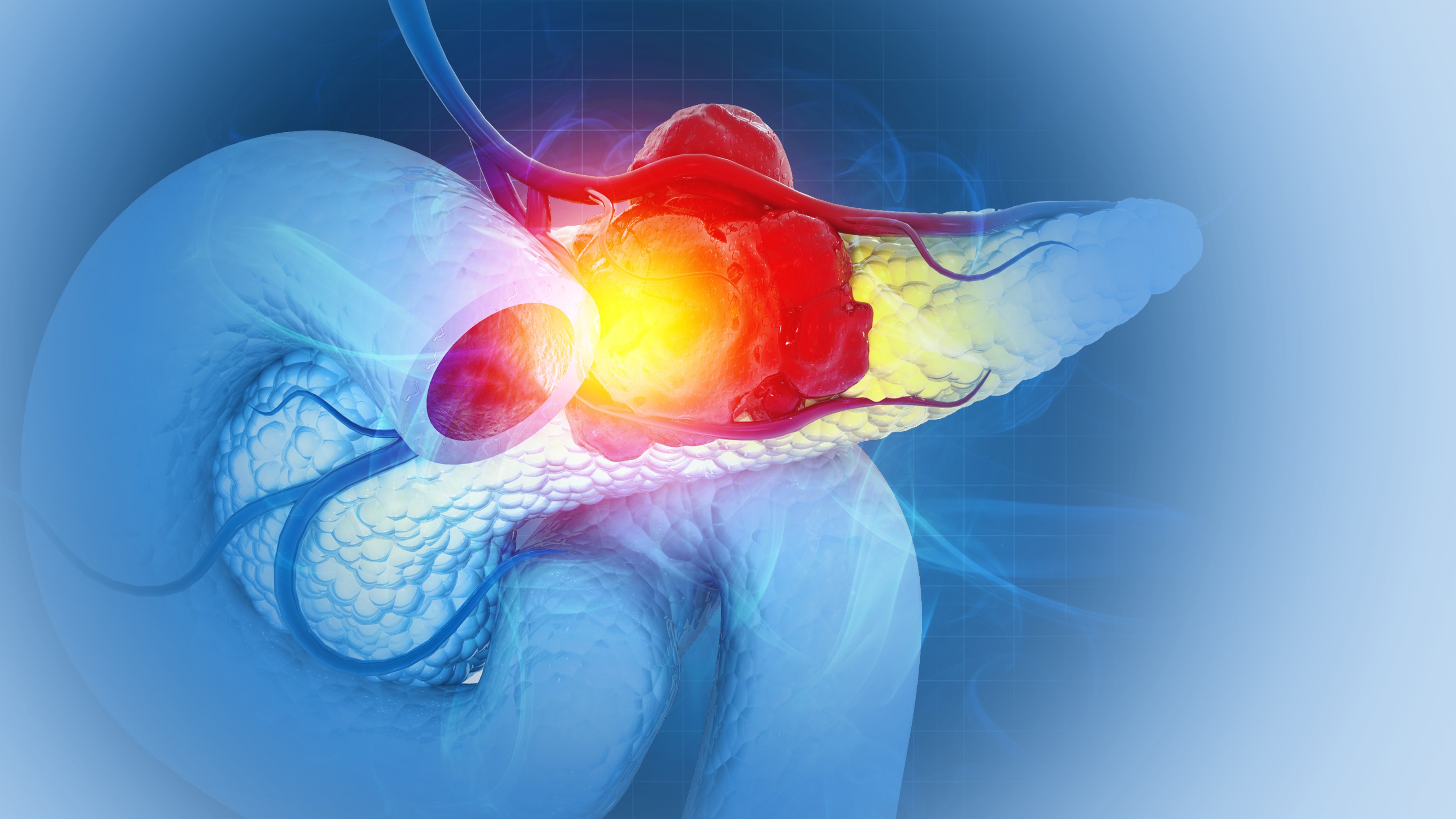

The insights from both paths of research could lead to the use of spider silks for rebuilding ligaments and for other medical and nano-engineering applications.

The study will be published in the Feb. 2 issue of the journal Nature.

You can follow LiveScience staff writer Jennifer Welsh on Twitter @microbelover. Follow LiveScience for the latest in science news and discoveries on Twitter @livescience and on Facebook.

Jennifer Welsh is a Connecticut-based science writer and editor and a regular contributor to Live Science. She also has several years of bench work in cancer research and anti-viral drug discovery under her belt. She has previously written for Science News, VerywellHealth, The Scientist, Discover Magazine, WIRED Science, and Business Insider.

Live Science Plus

Live Science Plus